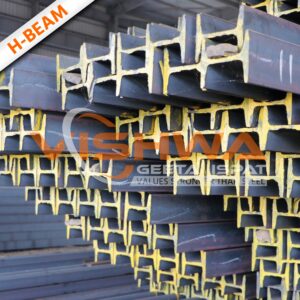

I Beam Supply for Large Structures

MS Beam Weight Chart

Accurate MS Beam weight is critical for structural design, load calculations, and project execution, as it directly impacts strength assessment, quantity estimation, and overall project cost. A standard MS Beam weight chart helps engineers, structural consultants, contractors, fabricators, and procurement teams verify MS Beam weight per meter, calculate steel tonnage accurately, and avoid risks caused by short-weight or non-standard MS Beam sections.

MS Beam Size & Weight Chart (ISMB)

Quick reference for MS Beam / I-Beam (ISMB) section sizes and weight per meter. Actual weight may vary slightly as per rolling tolerances.

| Designation | Size (Depth × Flange) mm | Weight (kg/m) | Common Use |

|---|---|---|---|

| ISMB 100 | 100 × 50 | 8.9 | Light frames, supports |

| ISMB 125 | 125 × 70 | 13.3 | Sheds, small beams |

| ISMB 150 | 150 × 75 | 15.0 | Beams, lintels |

| ISMB 175 | 175 × 85 | 19.6 | Platforms, mezzanine |

| ISMB 200 | 200 × 100 | 24.2 | Industrial structures |

| ISMB 225 | 225 × 110 | 31.1 | Heavy framing |

| ISMB 250 | 250 × 125 | 37.3 | Longer spans |

| ISMB 300 | 300 × 140 | 46.0 | Heavy loads |

| ISMB 350 | 350 × 140 | 52.4 | Large sheds |

| ISMB 400 | 400 × 140 | 61.6 | Warehouses, columns |

| ISMB 450 | 450 × 150 | 72.4 | High load beams |

| ISMB 500 | 500 × 180 | 86.9 | Heavy structures |

| ISMB 600 | 600 × 210 | 123.0 | Major span/load work |

MS Beam Weight Chart and Price

As an experienced MS Beam trader, Vishwa Geeta Ispat offers competitive MS Beam prices, transparent pricing, and best working rates for bulk MS Beam orders. With access to multiple steel plants, we ensure price stability, consistent section quality, and timely dispatch across India.

Terms and condition

- GST @18% will be charged extra.

- Loading @ Rs 275/- per mt will be charged extra.

- Transit insurance will be charged extra @ 15-25 per ton.

- Transportation costs will be charged extra.

- Dispatch 1-7 working days from receipt of advance.

- Length of the material would be 6 meters. Special length also provided.

- Weight tolerance +/- 0.5% is to be allowed.

- Rates are subject to change as per the hourly market situation.

- Products are subject to availability.

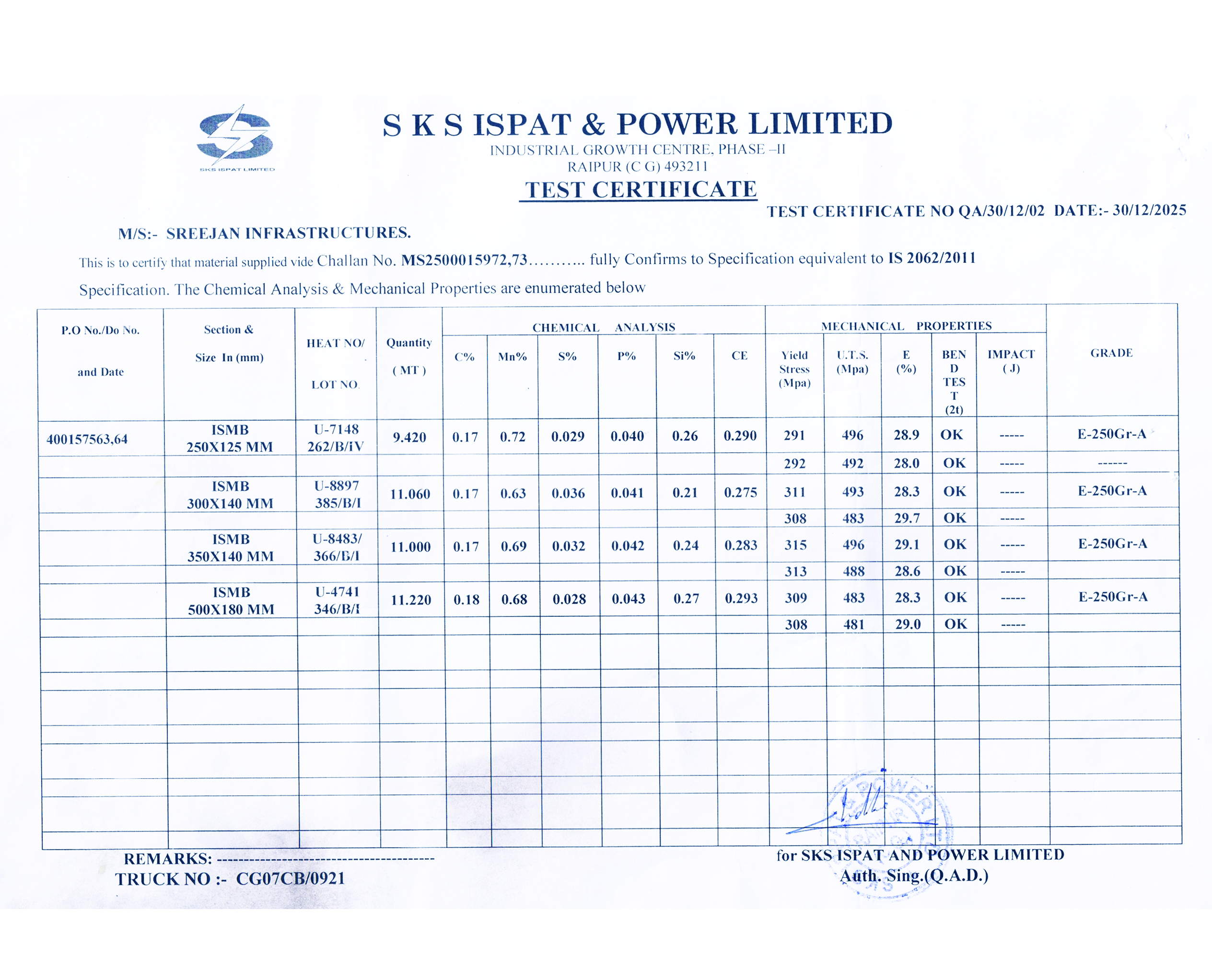

MS Beam, Steel Beam & Quality Assurance

Along with I Beams, Vishwa Geeta Ispat deals in MS Beams and steel beams for industrial and fabrication requirements. Accurate sizing and weight verification are essential for structural reliability. A dedicated team checks MS Beams and iron beams directly at the factory. I Beam sizes, actual I Beam weight, and values as per the standard I Beam weight chart in kg are verified before loading. Each steel beam is dispatched with a proper test certificate to ensure quality and compliance. Vishwa Geeta Ispat | Values Stronger Than Steel

Test certificate

Frequently Asked Questions

MS Beam, also known as Mild Steel Beam or IS Beam, is a structural steel section used for load-bearing applications in buildings, industrial sheds, bridges, platforms, and infrastructure projects. MS beams are widely used in residential, commercial, and industrial construction across India.

Common types of MS beams include ISMB (Indian Standard Medium Beam), ISHB (Indian Standard Heavy Beam), and H-Beams. These MS beam sections are selected based on span, load requirement, and structural design needs

MS Beam weight per meter is critical for structural calculations, BOQ preparation, and project costing. Accurate MS beam weight ensures correct load assessment, avoids short-weight supply, and helps engineers maintain safety and compliance.

MS Beam weight is calculated based on standard IS specifications considering flange width, web thickness, depth, and density of mild steel. Most buyers refer to an MS Beam weight chart or ISMB weight table for accuracy.

MS Beams are available in multiple standard sizes such as ISMB 100, ISMB 150, ISMB 200, ISMB 250, ISMB 300, and heavier sections. Size selection depends on span length, structural load, and application type.

MS Beams are primarily designed to resist bending loads, while MS Columns are designed to handle axial loads. In steel structures, MS beams act as horizontal members and columns as vertical load-bearing elements

MS Beam price in India depends on section size, weight, steel grade, plant source, and market conditions. Buyers usually search for “MS Beam price today” or “ISMB beam rate per kg” for real-time pricing.

Choosing a reliable MS Beam supplier ensures accurate weight, standard IS specifications, genuine material, and timely delivery. Experienced steel traders with multi-plant sourcing offer better pricing stability and bulk supply reliability.

Yes. MS Beams are widely used in industrial sheds, warehouses, factories, bridges, and heavy fabrication due to their high load-bearing capacity, strength, and structural stability.

MS Beams are typically manufactured using mild steel grades as per Indian Standards such as IS 2062. The steel grade affects strength, ductility, weldability, and overall structural performance.

Yes. MS Beams offer excellent weldability and workability. They can be easily cut, drilled, bolted, and welded, making them suitable for fabrication, structural framing, and custom steel work.

Accurate MS Beam weight ensures correct steel quantity, prevents financial loss due to underweight material, maintains structural safety, and avoids disputes during inspection, billing, and site execution.

Other Products